Fuel Cell Electric Vehicle Hydrogen Refueling Technologies

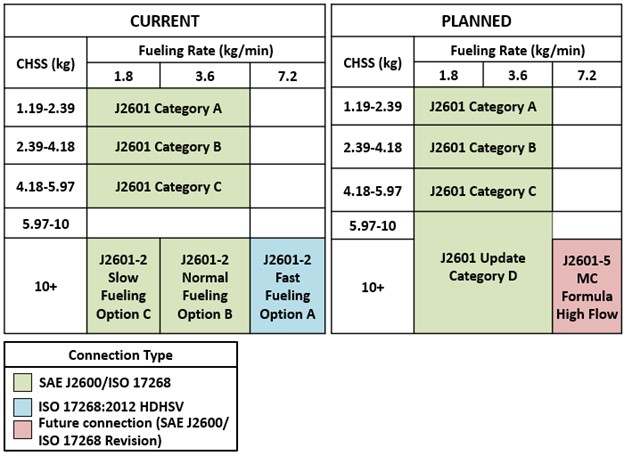

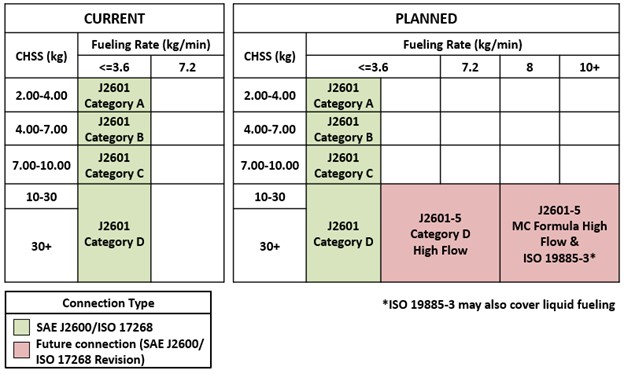

All hydrogen stations in California dispense gaseous hydrogen (hydrogen may be stored as a liquid on-site). For gaseous hydrogen fueling, the main standards are SAE J2600, SAE J2601, SAE J2601-2, SAE J2601-5, and the in-development ISO 19885 for high flow heavy-duty vehicle fueling. Compared to BEV charging, there are fewer hardware configurations available for hydrogen fueling, with the main nozzle designs harmonized between SAE J2600 and ISO 17268, and an additional heavy-duty design for fast flow (7.2 kg/min) fueling detailed in ISO 17268: 2012 to accompany SAE J2601-2.

At present, all commercial fuel cell electric vehicles store hydrogen on-board as a compressed gas, although fuel systems for on-board liquid storage are starting to become available, with ISO 13985 covering liquid hydrogen storage for mobile applications.

Table 1 - 350 Bar (H35) Fueling Rates by Standard

Table 2 – 700 Bar (H70) Fueling Rates by Standard

Key parameters for hydrogen fueling include:

- Tank rated pressure - In the U.S., two pressures are available for fueling: 350 bar (H35) and 700 bar (H70), as defined in SAE J2601.

- Hydrogen fueling delivery temperature - In the standard, there are three fuel delivery temperature categories: -40oC (T40), -30oC (T30), and -20oC (T20).

- Compressed Hydrogen Storage System capacity - There are four categories of CHSS Capacity, which are divided by maximum stored hydrogen (kg) at a full state-of-charge: Category A, B, C, and D.

- Vehicle-station communications - Fills can be characterized by "non-communications" or "communications." The type of fill is determined at the beginning of the fill session by the station based on whether it receives data signals and whether they meet the defined requirements in SAE J2799. At a minimum, all stations should be able to complete a fill without vehicle communications.

- Fueling gas flow rate calculation method - There are two main methods for calculating fueling gas flow rate: Table-Based Fueling Protocol and Mass and Thermal Capacity (MC) Formula.

- The Table-Based Fueling Protocol uses look-up tables included in the standard that are based on computer modeling. The appropriate table is determined by the vehicle and station conditions measured at the start of the fill session. The look-up tables are further divided into a communication fill or non-communication fill. The data used to determine the appropriate look-up table are hydrogen delivery temperature and CHSS capacity category (the dispenser will not initiate the fill if the CHSS pressure rating is less than the dispenser rating).

- The MC Formula uses a dynamic, analytical approach to calculate the pressure ramp rate in real time - once at initiation, then update the pressure ramp rate for the fill session duration. The MC Formula uses a regression equation to calculate the appropriate PRR, considering ambient temperature, initial CHSS pressure, mass flow, and gas pressure and temperature measured at the nozzle outlet. The MC Formula also has non-communications and communications options, which differ in how the pressure endpoint is calculated, with the non-communications method assuming "Worst Case" conditions, which are provided in the look-up tables.

As of 2023, there are over 1,000 hydrogen refueling stations globally. In California, there are over 60 light-duty stations with over 10 heavy-duty stations planned or operating. A comprehensive list of hydrogen stations in the state are available through the California Energy Commission ZEV dashboard as well as the Hydrogen Fuel Cell Partnership.

At present, all commercial fuel cell electric vehicles store hydrogen on-board as a compressed gas, although fuel systems for on-board liquid storage are starting to become available, with ISO 13985 covering liquid hydrogen storage for mobile applications.