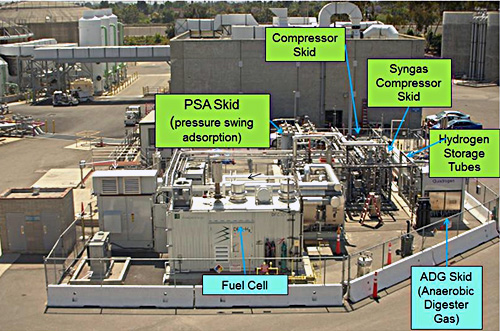

The National Fuel Cell Research Center (NFCRC) demonstrated the first-in-the-world high temperature fuel cell Tri-Generation system at the Orange County Sanitation District (OCSD) through a public/private partnership. The system, which was fueled on biogas derived from wastewater treatment, simultaneously produced electricity, heat, and hydrogen fuel. The installation was coupled with a hydrogen fueling dispenser which refueled fuel cell vehicles with bio-hydrogen. Tri-Generation technology was first conceived at the NFCRC in 2002 and then developed further through research and collaboration with Air Products & Chemicals, Inc. and FuelCell Energy, Inc., eventually leading to the demonstration at the Orange County Sanitation District. The partners involved in the program included Air Products and Chemicals, FuelCell Energy, the U.S. Department of Energy, the California Air Resources Board, South Coast Air Quality Management District, and the Southern California Gas Company.

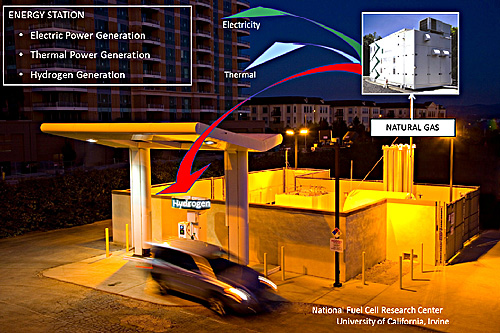

The Schematic below describes how the concept for a Tri-Generation system could be integrating into a hydrogen fueling station. Most hydrogen fueling stations today, including the UC Irvine hydrogen station shown below, are supplied with hydrogen that is produced in a central plant and then delivered.

Above is a picture of the UC Irvine hydrogen fueling station, managed by the National Fuel Cell Research Center (NFCRC). It is currently the busiest hydrogen station in the world, serving over 6,000 FCEV's in California.

Currently, hydrogen is produced off site and delivered to the fueling station.

A schematic is inserted to show how hydrogen could be produced on site through the use of a Tri-generation system. The system would simultaneously produce electricity and heat for nearby buildings and homes.

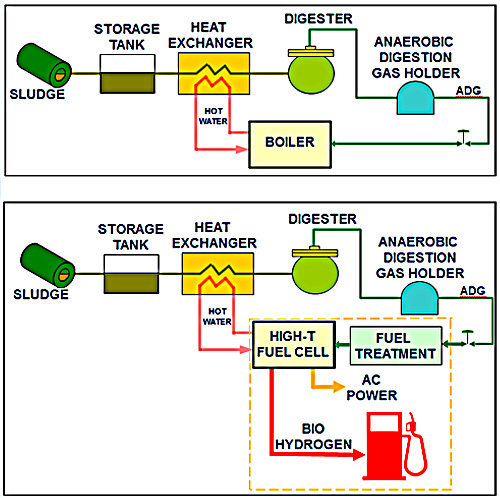

At a typical wastewater treatment plant, biogas is produced and simply combusted in a boiler to provide heat for the wastewater treatment operations. At the OCSD, the biogas was fed to a high temperature fuel cell that used the novel Tri-Generation system to simultaneously produce renewable electricity and heat to support wastewater treatment operations, as well as hydrogen to refuel hydrogen powered vehicles.

This schematic shows a typical wastewater treatment process. The sludge collected at a central facility is headed and anaerobically digested to produce a methane-rich gas. That bio-methane is burned in a boiler to produce heat that sustains the process.

At the Orange County Sanitation District, a high temperature fuel cell system was integrated into the wastewater treatment process to produce the electricity, and heat for plant operations.

In addition to those two products, the high temperature fuel cell is producing a third product – renewable hydrogen – which refueled hydrogen powered vehicles.

The first real-world demonstration of this system went into operation on August 16th 2011, operating off of renewable digester gas from the wastewater treatment process at the orange county sanitation district. The NFCRC was one of the principal partners along with the technology providers.